One-Size-Fits-All COVID Vaccination Narrative and Internet Censorship

Dr. Tracy Beth Hoeg, MD PhD, writing on the website of Dr. Vinay Prasad (who was interviewed by Saagar and Krystal). Hoeg is concerned about one-size-fits-all vaccination and internet censorship of comments (even by doctors) that are off-narrative):

My interpretation of the data is vaccines continue to be the best tool we have to prevent severe disease. When health care workers could get vaccinated, I got mine the first day I could. That being said, I had wished my parents and older patients could have gotten theirs before me. I begged unsuccessfully to extend my time between the first and second dose because of cardiac side effects I had had from the first dose (which came on quite severely while running). I continue to strongly recommend vaccines to my patients (and now boosters for all over 40-50 or with specific risk factors) and help facilitate vaccination appointments for them and talk them through the data. I recommended to my younger healthier adult patients to only get one dose if they had already been infected based on the data we already had late last winter and a need to preserve vaccinations. I have always felt, based on the data that healthy children were at very low risk and vaccinating them before older adults across the world was unethical and irresponsible. You and I wrote about this for the Atlantic with Monica Gandhi. I still stand by what we said.Over the spring and summer, the evidence suggested vaccines were very effectively preventing transmission, which was a major rationale for vaccinating everyone. But I also knew, as did you, in the spring that a serious vaccine adverse effect could quickly tip the individual harms of the vaccine beyond those of the benefits for healthy children. And I actually tweeted about the uncertainty about the risk-benefit ratio of vaccination in healthy boys on June 10th as the myocarditis data were accumulating from Israel and our own CDC.

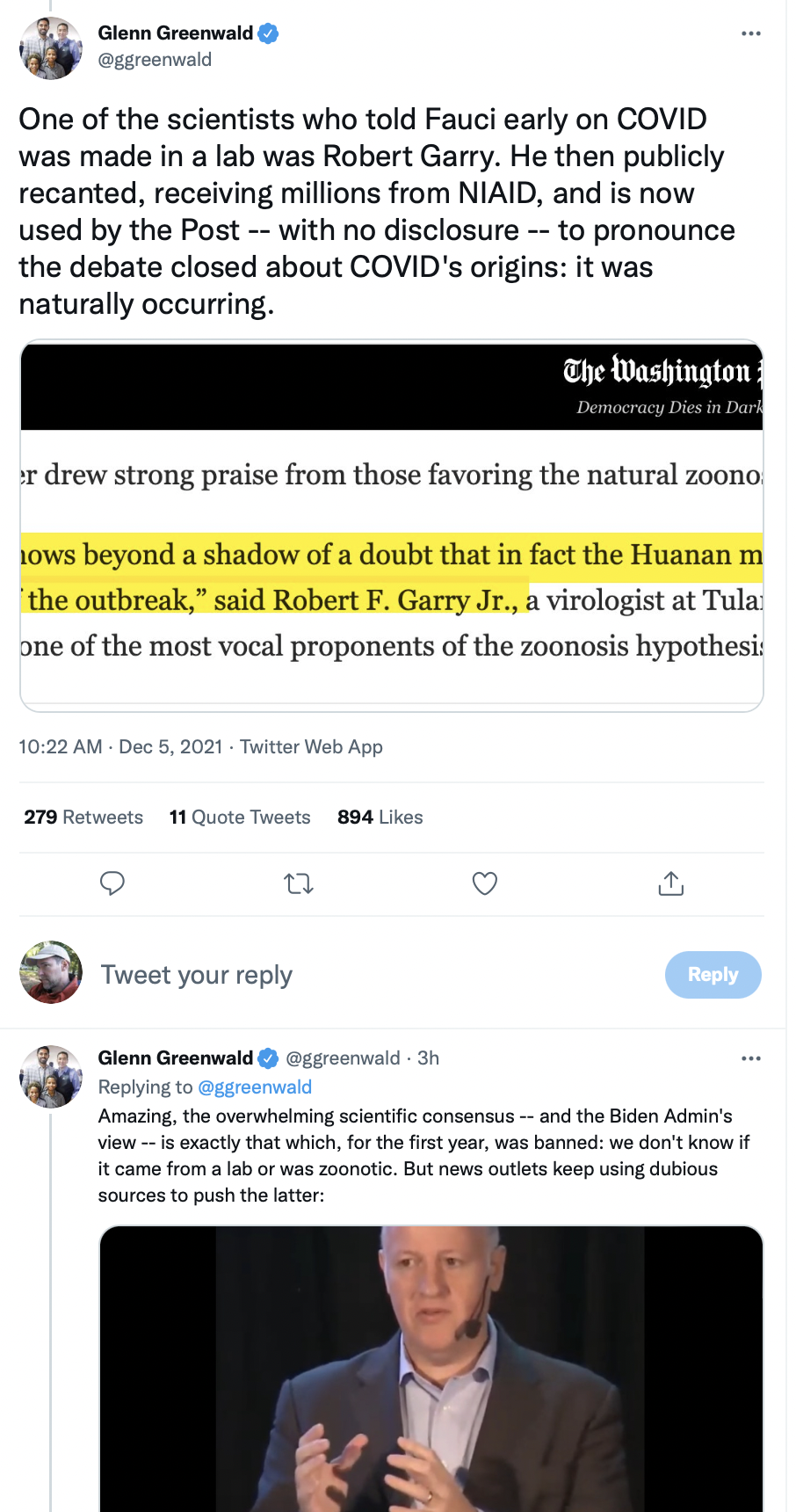

My tweet was censored by Twitter and that landed me on Tucker Carlson (which I had never watched). I understand the political nature of this pandemic (certainly on social media) but the censorship of an issue as important as vaccine-associated myocarditis in boys and young men really got under my skin. I was receiving texts and messages from physicians I knew seeing post-vaccination myocarditis in young boys and men across the country and I was vexed the CDC did not prioritize getting an accurate, stratified estimate of this occurrence. Certainly, as a mom I wanted to have a reasonable sense of the benefits vs risks in my old children. At that time I was glad to connect with the cardiologist John Mandrola because we are very like-minded, particularly on this issue (we’ll discuss our study below).

I have consistently viewed attempts to estimate the rates and define the severity of a vaccine side effect as highly pro-vaccine. Anything else, especially when it comes to children, will quickly erode public trust and fuel overall vaccine hesitancy. Especially now with the vaccines’ limited and transient impact on transmission, we need to be considering each individual’s risks from COVID-19 and their expected benefits (and risks) from each dose. The most important factors to consider in this analysis include age, sex, risk factors for severe COVID-19 and history of infection.

What still boggles my mind, is when you just do the simple math using the German study of infection-hospitalization rates in healthy children, you get a 1/2400 chance a healthy 12-17 year old will be hospitalized for COVID-19 requiring specific covid treatment (this eliminates incidental hospitalizations) and, now with omicron, that is likely around 1/5000 risk (or lower) and yet the rate of symptomatic post vax myocarditis after dose 2 in this age group is around 1/3000 (see below) and yet so few seem to be questioning dose 2 for them (when mathematically it’s the wrong decision), let alone dose 3, which seems a clear mistake to mandate without evidence of benefit. . .